But things were not working quite right, and (very) eventually a subtle misalignment was discovered.

An earlier version of this blog contained an error

– see ‘False start’ below

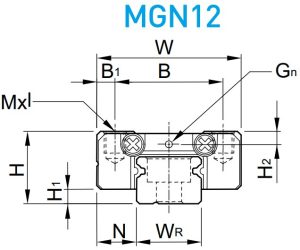

This kind of rail, often known by the ‘MGN’ part number from Hiwin’s product line, regardless of actual manufacturer, where MGN12 is a 12mm wide rail (‘Wr’ in the diagram right).

They were originally intended for precision machinery, and there are exacting ways to mount them to achieve their best potential involving machined surfaces and a register edge.

However, they will also bold down to aluminium extrusions for less critical applications.

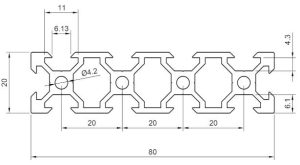

MGN12 rail will sit pretty flat on 20mm pitch T-slot extrusion (left) – running along the slot, with its 12mm width bridging the 5mm slot (which is ~6mm wide at the metal surface).

MGN12 rail will sit pretty flat on 20mm pitch T-slot extrusion (left) – running along the slot, with its 12mm width bridging the 5mm slot (which is ~6mm wide at the metal surface).

3mm screws hold the thing together, threading into suitable T-nuts slid into the extrusion.

This same scheme can work with 20mm pitch V-slot profile (right – where the difference in shape is there to allow chamfer-edged guide wheels to roll along the slots).

And it my case the scheme does work as the 12mm rails have ~11mm flat between its chamfers, and the aluminium profile flat lands are just over 9mm apart across the slots – so just under 1mm of flat contact surface on either side of the slot.

However, after much measuring (and see ‘False start’ below), a ground straight-edge showed me that the three broader flats on the profile surface are co-planar (within a handful of microns, by eye with a light), while the two end flats are between 20 and 40μm below that plane – and I am trying to mount my two rails on the outer two slots.

Let me stress here that there is no criticism of the supplier: I am trying to do ‘too much’ with an extrusion made for rigidity and guide wheels rather than micron accuracy.

Anyway, my next move is packing up the rail on the outside edges to see if this will fix it.

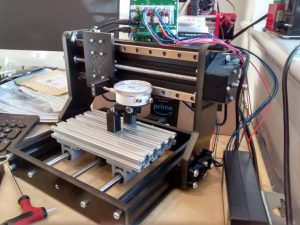

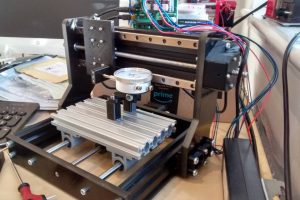

If you need to cut acrylic or aluminium cleanly, with reasonable precision, it is worth spending ~£600 to get one of the better desktop machines that now available – rather than modifying a three year old £120 desktop cnc like the one on the left (even though this has been interesting and only cost an extra ~£100).

False start

This same blog contained false information for a few days up to this edit – I was blaming the chamfers on the extrusion slot edges and the rail edges for interacting, allowing the rail to sit at a slight angle. This was wrong – sorry about that 🙁

Image sources:

V-slot extrusion: Ooznest – a great UK SME from where I have bought custom cut-and-tapped V-slot rail, and would do the same again

T-slot extrusion: RS Components – need I say more.

MGN12 rail: Hiwin – respected maker of linear guide rails

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News

It does make me appreciate not having to worry about mechanical precision.. very often, and also appreciate the ease with which I can just order a 0.1% resistor if I need to. 🙂 Of course, I’ve had times where I’ve needed to temperature coefficients or other sources of error in my analog circuits, so I suppose none of us get to ignore all of the ways that things can go wrong.

Good afternoon Mr Kurt

First: an apology to you, and all other readers – I made a factual error in the original blog, now corrected. It was not the fault of chamfers, but just expecting too much of extrusions.

And indeed, a precision resistor or a crystal are such lovely ways to get a lot of accuracy.

I seem to be floundering in a mechanical world equivalent to filing into the side of carbon composition resistors to trim thinks 🙁

(no wonder mechanical engineers take so long to train… 🙂